In the wave of digital transformation in manufacturing, production interruptions caused by equipment downtime and resource waste due to over-maintenance have become key pain points restricting enterprises from reducing costs and increasing efficiency. Traditional preventative maintenance relies on historical data, often falling into the dilemma of "over-maintenance" or "under-maintenance." Condition-based maintenance (CBM), with its real-time monitoring and precise analysis, is becoming a core solution to break this deadlock, providing a new path for enterprises to maximize asset value.

I. Condition-Based Maintenance: Saying Goodbye to "Empirical Thinking" and Moving Towards "Data-Driven"

Condition-based maintenance is an operation and maintenance model that accurately judges the health status of assets by collecting real-time equipment operation data and combining it with historical performance baselines and expected indicators. It differs from preventative maintenance that relies on fixed cycles and transcends the passive model of reactive repair—the support of sensors and IoT technology transforms equipment from "passive repair reporting" to "proactive early warning." By continuously monitoring key parameters such as equipment vibration, temperature, and pressure, the system can identify potential fault signs and issue early warnings at the initial stage of equipment performance degradation, allowing maintenance personnel sufficient time to plan repairs.

II. Core Advantages: Finding the Optimal Balance Point for Maintenance

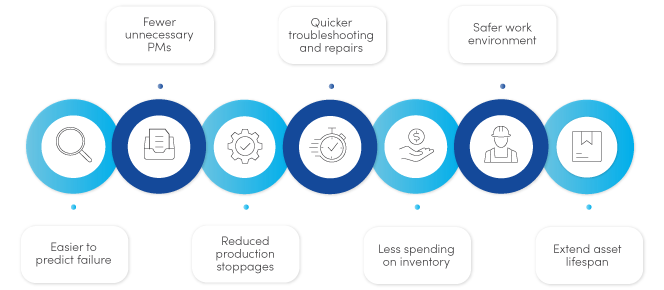

The core value of condition-based maintenance lies in accurately grasping the balance point of "maintenance timing." On the one hand, it avoids the damage caused by over-maintenance—for example, repeatedly adding grease to already lubricated parts not only reduces equipment efficiency but also increases contaminant accumulation, accelerating machine aging. On the other hand, it prevents sudden downtime caused by "operating with defects," nipping problems in the bud.

The advantages of this model have been proven in practice: McKinsey research shows that a large technology manufacturer, after introducing a condition-based maintenance framework, achieved approximately 30% savings in labor, downtime, and parts costs by integrating industrial IoT data with historical service records. IBM further points out that this model can help manufacturing companies reduce maintenance costs by 15%-20% while increasing asset availability by 20%, offering multiple benefits such as extending equipment lifespan, enhancing production safety, and ensuring product quality.

III. Technological Foundation: Real-time Monitoring and Data Analysis as Dual Drivers

The implementation of condition-based maintenance relies on two core technologies. First, sensor and connectivity technologies: various high-precision sensors can collect core data on equipment operation in real time, while industrial IoT platforms ensure the stability and timeliness of data transmission, making the health status of each piece of equipment "verifiable." Second, data analysis capabilities: by comparing real-time data with historical baselines and industry standards, the system can build equipment health assessment models and accurately identify early warning signals of performance anomalies.

Compared to traditional maintenance models, this technology combination upgrades maintenance decisions from "experience-based" to "data-driven," transforming maintenance work from "periodic execution" to "on-demand initiation," significantly improving maintenance efficiency and resource utilization.

IV. Practical Value: Cost Reduction and Efficiency Improvement, Empowering Sustainable Enterprise Development

In practical applications, condition-based maintenance brings multiple benefits to manufacturing enterprises: First, it reduces unplanned downtime, provides early warnings of potential faults, and ensures continuous and stable production line operation; second, it extends asset lifespan, with precise maintenance preventing excessive equipment wear and tear and maximizing asset utilization value; third, it optimizes manpower and spare parts costs, eliminating the need for maintenance personnel to conduct meaningless inspections, and allowing for precise allocation of spare parts inventory based on early warnings, reducing capital tied up in inventory.

In the long run, condition-based maintenance is not only an innovation in operation and maintenance models but also a crucial tool for enterprise digital transformation. It transforms equipment management from a "cost center" to a "value center," building a strong competitive advantage for enterprises by reducing costs and increasing efficiency in a fiercely competitive market.

Recommended Products

|

Advulq-20-50-A-P-A-S2 |

E191533-1 |

WSR-12 |

|

ADVU-40-30-A-P-A-S2 |

CPE10-M1H-5L-QS-6 |

ESN-10-50-P |

|

Advulq-16-15-A-P-A-S20 |

CPE10-M1BH-5J-M7 |

ADN-16-15-I-P-A |

|

CPE10-M1BH-3OLS-M5 |

DSNU-20-125-P-A |

EQ96KL |

|

Advu-25-25-P-A |

6EP1961-3BA01 |

3SB3 802-0AA3 |

|

ADVU-32-20-P-A |

6ES5 700-8MA11 |

6ES7 340-1AH02-0AE0 |

|

3SB3 500-0AA21 |

MXH6-30 |

6ES7 392-1CM00-0AA0 |

|

MFH-3-1/8 |

ADN-16-100-A-P-A |

CPE14-M1BH-5/3G-1/8 |

|

CQ2B32-5DZ |

6ES5 712-8AF00 |

3SB3420-1PB |

|

KMYZ-7-24-10 |

DNC-40-25-PPV-A |

CPE14-M1CH-5LS-1/8 |

|

3SB12 14-0AH01 |

6ES7 322-1BH01-0AA0 |

6ES7 193-0CA10-0XA0 |

|

PUN-8X1,25-S-1-SW |

6ES7 322-1BH01-0AA0 |

M22-DL-R |

|

ADN-12-60-A-P-A |

AC1216 |

MS6-LRP-1/4-D5-A8 |

|

CPV10/14-VI-BG-RW |

CPE14-M1BH-3GL-1/8 |

ADN-20-10-I-P-A-10K8 |

|

QSMLL-1/8-6 |

Dyef-M6-Y1F |

Aevulq-20-15-P-A |

For more product information, please contact us:

Manager: Leonia

Email: sales11@amikon.cn

Whatsapp: +8618030175807

New Blog

Supplyed

525011

parts to

23253

customers in

148

countries